Precision-engineered plugs for demanding applications

Precision-engineered for performance and durability, sealing plugs by The Lee Company provide exceptional reliability across a variety of applications. Our industry-leading expansion plugs are trusted for their ability to create secure, leak-proof seals in a variety of systems.

sealing Plugs designed to meet the highest standards

With decades of engineering expertise, our sealing solutions are designed to meet the highest standards for safety, efficiency, and longevity for applications in a wide variety of industries.

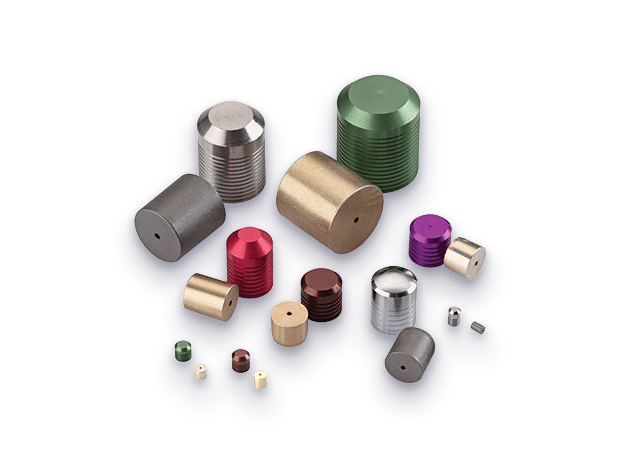

Lee Plug® Expansion Plugs

The founding, flagship product from The Lee Company. Lee Plugs are manufactured to exacting tolerances. Every process is precisely controlled. Each lot of pins and plugs undergoes a rigorous inspection and acceptance testing. This ensures performance when any failure could be catastrophic.

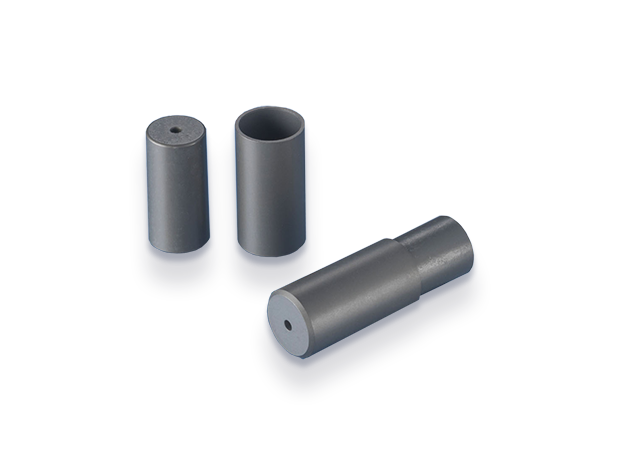

6000 Series Betaplug®

The 6000 Series Betaplug is built for high-pressure automotive systems. Design the 6000 Series Betaplug into systems up to 7000 psi, and choose from parts that range from 4 mm to 8 mm in diameter.

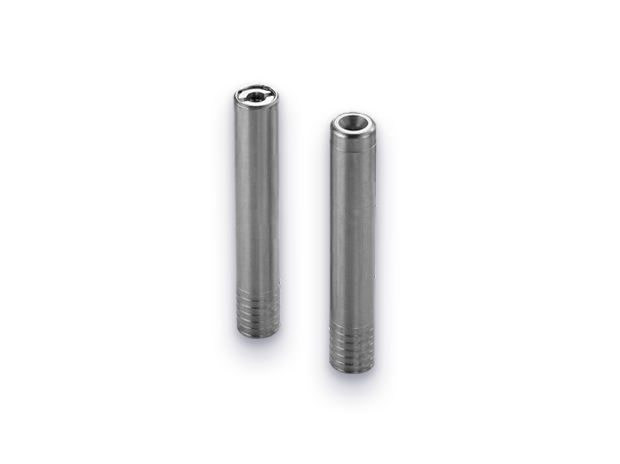

Short Betaplug®

The Short Betaplug was developed to optimize process and product settings and allows for the shortest installed height. Install the Short Betaplug in systems up to 500 psi, and choose plugs that range from 5 mm to 20 mm in diameter.

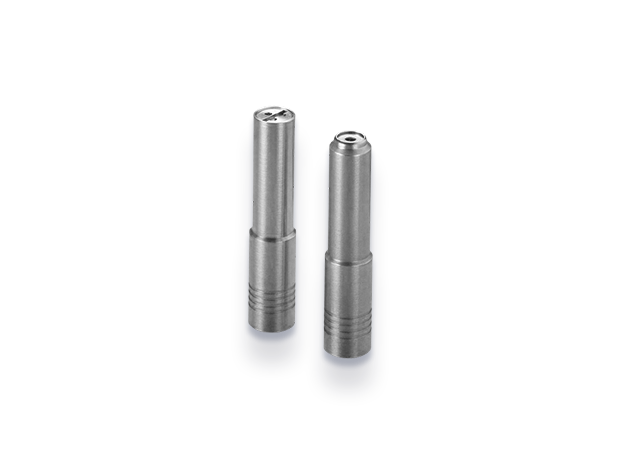

DL Series Plug

The DL Series Plug* features Drive Locking® technology, purposely designed to facilitate reliable automated installation and verification processes, allowing customers to reduce scrap and labor costs while improving the reliability of their production processes. *Patent Pending

Lee R.F.O.® (Radial Force Only) Plugs

Lee R.F.O. Plugs are designed to seal holes in thin walls or fragile materials. Designed to be easily removable, these plugs do not require a support shoulder and the installation system ensures that no downward pressure is applied to the product.

Lee QIP® (Quick Installation Plug) Plugs

The Lee QIP was developed to provide an easier method of handling and installing the smallest plug sizes. This is accomplished by pre-installing the pin into the plug. This pre-assembled component adapts more easily to automated installation.

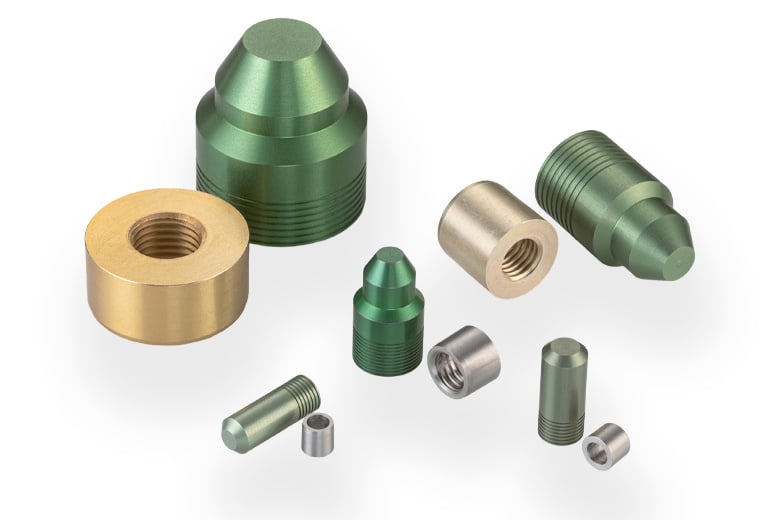

Lee A.F.O.® (Axial Force Only) Plugs

Unlike other plugs in our product family, A.F.O. Plugs are both removable and reusable due to their threaded design, which allows technicians easy access to sealed passageways. In spite of this, the A.F.O. Plug still seals up to 56,000 psi.

Lee Dual Sealing A.F.O.® Plugs

The Dual Sealing A.F.O. Plug comes with all the strength and ease of use offered by our regular A.F.O. Plugs, but with added safety features for use in hydraulic systems. The incorporation of an O-ring allows users to vent gas out of a side port or safely release trapped high-pressure gas.

Lee Cross Port Plugs

Lee Cross Port Plugs are a plugging solution specifically engineered to seal cross port passageways. This configuration is a variant of the original Lee Plug® that set industry standards over 65 years ago. A smooth wall design combined with the field-proven controlled expansion principle creates a permanent, leak-proof seal without O-rings or sealants.

EXPLORE OUR FULL RANGE OF PLUGS

The Lee Company is the original OEM and the only qualified aerospace supplier for expansion plugs. Whatever your specific application, The Lee Company can help you find the right solutions.

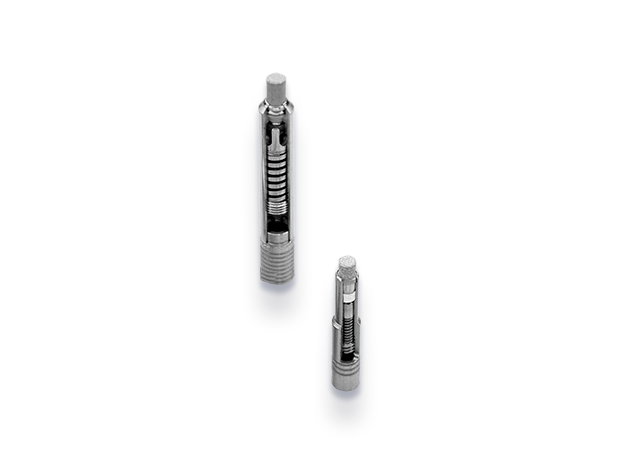

Safety Relief Valves

Designed to be fast-acting, these relief valves protect your systems from sudden pressure spikes. They come in low-leak and tight hysteresis options and undergo thorough testing for crack, flow, and reseat pressures.

Pressure Regulating Relief Valves

These valves ensure stability across the operating range and are available in various diameters and cracking pressures.

THERMAL RELIEF VALVES

Thermal relief valves protect fluidic systems from damage caused by thermal expansion by releasing small fluid volumes during rapid temperature changes.

High Pressure Safety Relief Valves

Built to handle severe operating pressures up to 5000 psi, preventing instability and damage. Available in various cracking pressures. The Hi-Q PRV is a line-removable unit designed for high-pressure, high-flow applications. It relieves up to 5400 psid and 19+ GPM, with a side inlet to minimize size and weight.

High Flow Pressure Relief Valves

The Hi-Q PRV is designed for applications that require both a high relief pressure and a high flow rate in a line removable unit (LRU). This valve can relieve pressures up to 5400 psid and flow rates over 19 GPM, and uses a side inlet flow path to minimize the installation boss size and weight.

ZERO LEAK RELIEF VALVES

Instead of relying on a metal-to-metal seal, these valves incorporate an elastomeric or polymeric seal for a zero-leak design, perfect for when eliminating leakage is a critical requirement of hydraulic or pneumatic applications.

NACE Compliant Relief Valves

The 0.281-inch NACE Compliant PRI® valve is built for harsh environments, using corrosion-resistant materials per NACE MR0175/ISO 15156. Available for pressures up to 3000 psi (screened/unscreened) and 5000 psi (screened).

Insert Style Pressure Relief Valves

Lee insert-style pressure relief valves offer secure, threadless installation with integral locking, eliminating leakage. Available in ball and poppet styles, they ensure fast response, stable flow, and high cracking pressures up to 220 bar.

Press-In Style Pressure Relief Valves

Lee press-in-style pressure relief valves feature a barbed design for secure installation in plastic housings, preventing leakage. Available in sizes from 2.5 mm to 8 mm, they ensure low leakage, repeatable cracking, and compatibility with various fluids, including medical-grade applications.

expert plug designs created for engineers, by engineers.

See for yourself why plugs from The Lee Company are designed for excellent performance even in extreme environments, and why the unique Lee Locking End Principle of controlled expansion creates a positive, reliable, leak- and trouble-free seal.