Fluid Control Pumps Built FOR MAXIMUM RELIABILITY AND PRECISION

The Lee Company offers pumps designed for key applications, including high pressure fluid movement and low pressure precision control for small volumes. Both ensure reliable performance, handle aggressive fluids with precision, and operate for thousands of hours with minimal maintenance.

Precision Engineered Pumps designed for Reliability

Our compact, durable pumps are designed to handle demanding conditions across various applications with ease. Every pump undergoes rigorous testing to ensure accuracy, efficiency, and long-term reliability. Available in various configurations, our pumps provide the perfect solution for your fluid handling needs. Explore our products below to find the pump that’s right for you.

Variable Volume DISPENSE Pumps

Designed for applications requiring adjustable flow rates, these pumps provide flexibility and precision in fluid control, commonly used in diagnostics and scientific instruments.

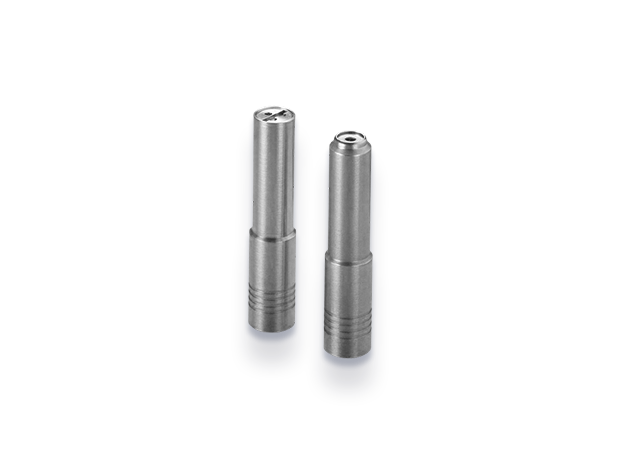

Fixed Volume DISPENSE Pumps

Delivering consistent and precise fluid volumes, these pumps are maintenance-free and ensure maximum reliability, particularly beneficial in medical equipment.

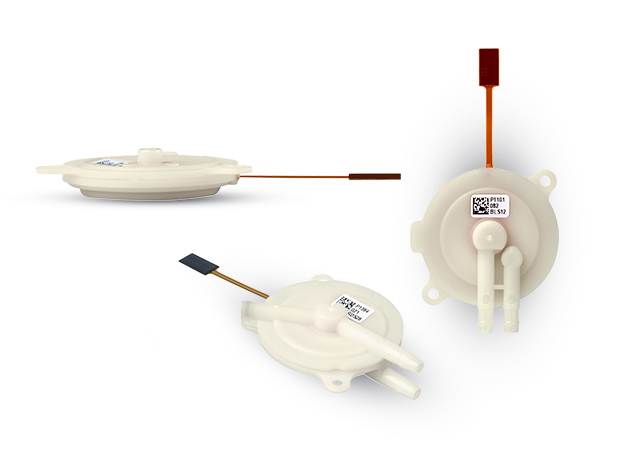

Piezoelectric Disc Pumps

Characterized by their compact design and rapid response, disc pumps are ideal for applications requiring high-frequency operation and minimal pulsation, such as in scientific instruments.

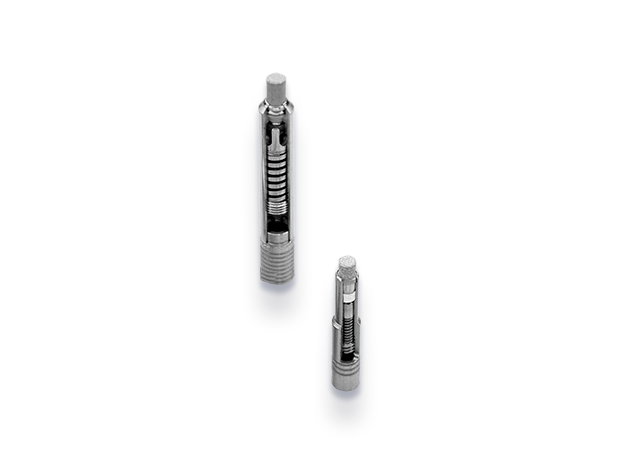

Axial Piston Pumps

The innovative axial piston design of Lee HPHT Pumps can generate up to 10,000 psi of pressure, is rated for operating temperatures up to 400°F, and dramatically improves reliability.

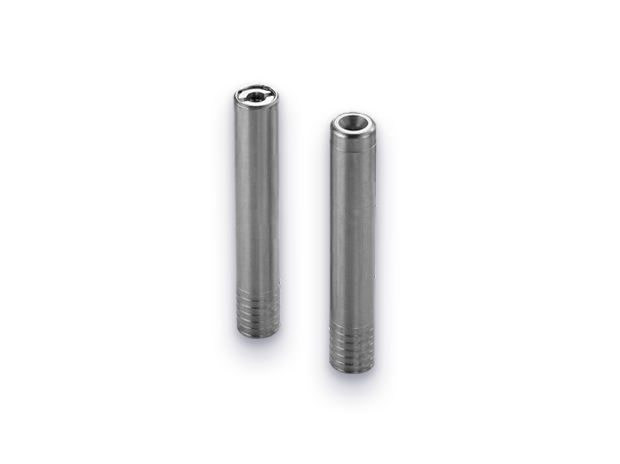

RADIAL PISTON Pumps

Designed to aid in self-priming at altitude and reduce cavitation. It includes integrated control electronics that allow full variable speed control for unparalleled flexibility. In addition, intelligence is built into the pump module to provide operational feedback such as pump speed, motor current, and fault monitoring.

EXPLORE OUR FULL RANGE OF PUMPS

Airplanes, cars and medical devices all need precisely engineered parts to perform at their best. At The Lee Company, we specialize in creating solutions tailored to your application. Browse our full product offering to discover pumps designed to optimize what you're building.

Safety Relief Valves

Designed to be fast-acting, these relief valves protect your systems from sudden pressure spikes. They come in low-leak and tight hysteresis options and undergo thorough testing for crack, flow, and reseat pressures.

Pressure Regulating Relief Valves

These valves ensure stability across the operating range and are available in various diameters and cracking pressures.

THERMAL RELIEF VALVES

Thermal relief valves protect fluidic systems from damage caused by thermal expansion by releasing small fluid volumes during rapid temperature changes.

High Pressure Safety Relief Valves

Built to handle severe operating pressures up to 5000 psi, preventing instability and damage. Available in various cracking pressures. The Hi-Q PRV is a line-removable unit designed for high-pressure, high-flow applications. It relieves up to 5400 psid and 19+ GPM, with a side inlet to minimize size and weight.

High Flow Pressure Relief Valves

The Hi-Q PRV is designed for applications that require both a high relief pressure and a high flow rate in a line removable unit (LRU). This valve can relieve pressures up to 5400 psid and flow rates over 19 GPM, and uses a side inlet flow path to minimize the installation boss size and weight.

ZERO LEAK RELIEF VALVES

Instead of relying on a metal-to-metal seal, these valves incorporate an elastomeric or polymeric seal for a zero-leak design, perfect for when eliminating leakage is a critical requirement of hydraulic or pneumatic applications.

NACE Compliant Relief Valves

The 0.281-inch NACE Compliant PRI® valve is built for harsh environments, using corrosion-resistant materials per NACE MR0175/ISO 15156. Available for pressures up to 3000 psi (screened/unscreened) and 5000 psi (screened).

Insert Style Pressure Relief Valves

Lee insert-style pressure relief valves offer secure, threadless installation with integral locking, eliminating leakage. Available in ball and poppet styles, they ensure fast response, stable flow, and high cracking pressures up to 220 bar.

Press-In Style Pressure Relief Valves

Lee press-in-style pressure relief valves feature a barbed design for secure installation in plastic housings, preventing leakage. Available in sizes from 2.5 mm to 8 mm, they ensure low leakage, repeatable cracking, and compatibility with various fluids, including medical-grade applications.

expert tips and guidance written for engineers, by engineers.

This is the ultimate guide for professionals selecting pumps for medical devices, offering critical insights for achieving precision, reliability, and optimal system performance.

Download your free copy now to discover:

- The fundamentals of pump selection and operation

- Key differences between continuous and reciprocating pumps

- Dispense characteristics and their impact on performance

- Strategies for managing fluid compatibility and environmental challenges

- Trade-offs and design challenges for achieving precision and reliability

- Common pump failures and how to prevent them

Gain the expertise needed to choose the right pump for your application.