PROTECT MISSION-CRITICAL SYSTEMS WITH LEE SAFETY SCREENS

Lee Safety Screens deliver compact, failsafe filtration to protect precision pneumatic and hydraulic components from rogue debris and contamination. Trusted in the most demanding environments, our safety screens are engineered for durability and performance.

Safety screen filters play a critical role in protecting vital components in hydraulic, fuel, lubrication, and pneumatic systems by reducing the rogue debris that can lead to sudden failure.

Speak directly with a Lee Technical Sales Engineer and get expert support tailored to your system’s unique demands.

HiGH-PERFORMANCE Safety Screen Filters for Critical Fluid Control Applications

Contamination can lead to failure in even the most advanced pneumatic and hydraulic systems. Lee safety screen filters are engineered to protect critical components in high-pressure, high-performance environments. With multiple fitting types and field-proven reliability, they offer compact, customizable solutions across a wide range of industries.

Press-In Style Safety Screen FILTERS

Press-In Style Safety Screens feature a barbed design for easy installation into plastic housings and fittings. These screens are composed entirely from 300 series stainless steel, and are available in multiple sizes for design flexibility.

INsert-Style SAFETY Screen FILTERS

Insert Style Safety Screens feature a locking end that utilizes a controlled expansion during installation, locking the screen securely into the wall of the retention hole. Each screen is constructed from stainless steel woven wire mesh and is available in sizes from 5.5 mm to 12 mm with micron ratings from 40 to 170.

Cartridge Style safety Screen FILTERS

Cartridge Style Safety Screens are compact filtration elements designed to be retained by the customer’s own assembly. Offered in a range of sizes from 5.5 mm to 8.0 mm, these screens are used in the automotive industry where precise filtration and flexible integration are required.

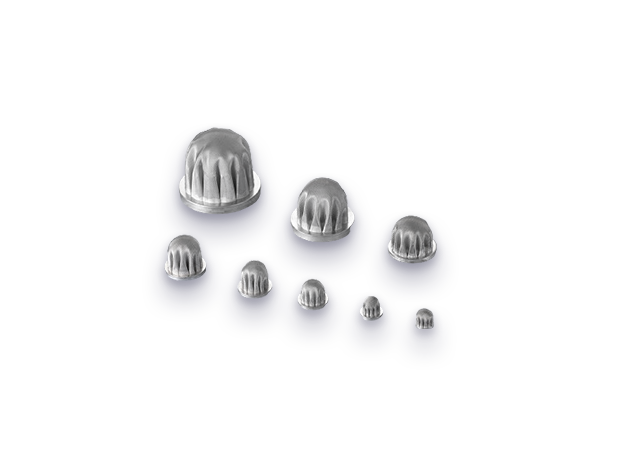

HI-BAR® Safety Screens

HI-BAR® Safety Screens are robust, high-strength filters developed by The Lee Company to meet the demands of space, motorsports, aerospace & defense system applications. With a weld-free, one-piece design, they withstand burst and collapse pressures up to 7500 psid and are available in standard and custom drilled hole sizes between 25 and 1500 microns.

Etched Safety Screens

Lee Etched Safety Screens feature an economical, one-piece stainless steel design with radial or circular convolutions that greatly increase the contamination carrying capacity of the screen. Available in multiple installation methods and hole sizes from 75 to 500 microns, these compact screens provide robust protection in space-constrained systems.

Strainers

Lee Strainers are high-capacity safety screens designed to protect critical components in demanding fluid systems. Manufactured from 304L stainless steel, they feature a robust, single-piece screen element rated for up to 500 psid. A corrugated design maximizes open area, increasing dirt-holding capacity while maintaining a compact, low-profile form.

Low Micron Wire Mesh Screens

Low Micron Wire Mesh Safety Screens deliver fine filtration with exceptional strength, using a sintered 316L stainless steel weave. Their radial convolutions increase contamination capacity, providing high-strength protection in a compact, space-efficient design.

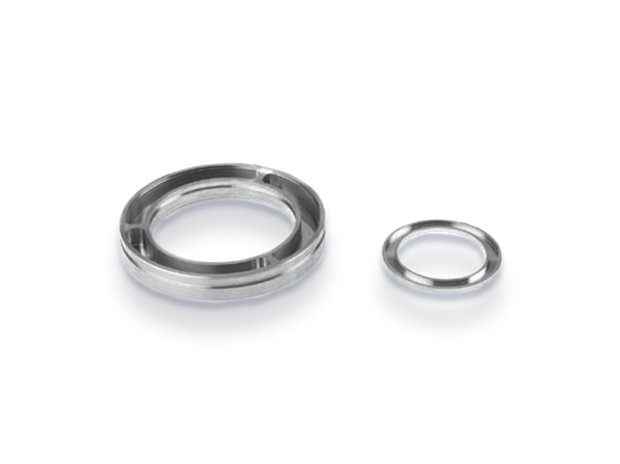

Screen Rings

Screen Rings are custom-designed filtration elements offered to the oil and gas industry. Made from NACE-compliant MP35N and rated for up to 10,000 psi, they allow fluid to flow along the outer diameter of cylinders while screening out contamination.

Detect and prevent contamination problems before they start.

Engineers across industries, from automotive and power generation to space and healthcare, understand the direct link between system cleanliness and system performance.

Explore how Lee’s approach to filtration safeguards performance across industries and why cleanliness should be the cornerstone of your system design.

What you’ll learn:

- Common sources of contamination

- The true cost of particle-related failures

- How to build a proactive filtration strategy