To orbit & beyond since the dawn of spaceflight

our History in space

At The Lee Company, we've been providing mission-critical miniature hydraulic and pneumatic components for space system applications for over sixty years. Lee components have been involved in spaceflight since before NASA existed, contributing to space exploration, telecommunications, satellite observation, and recent commercial New Space efforts.

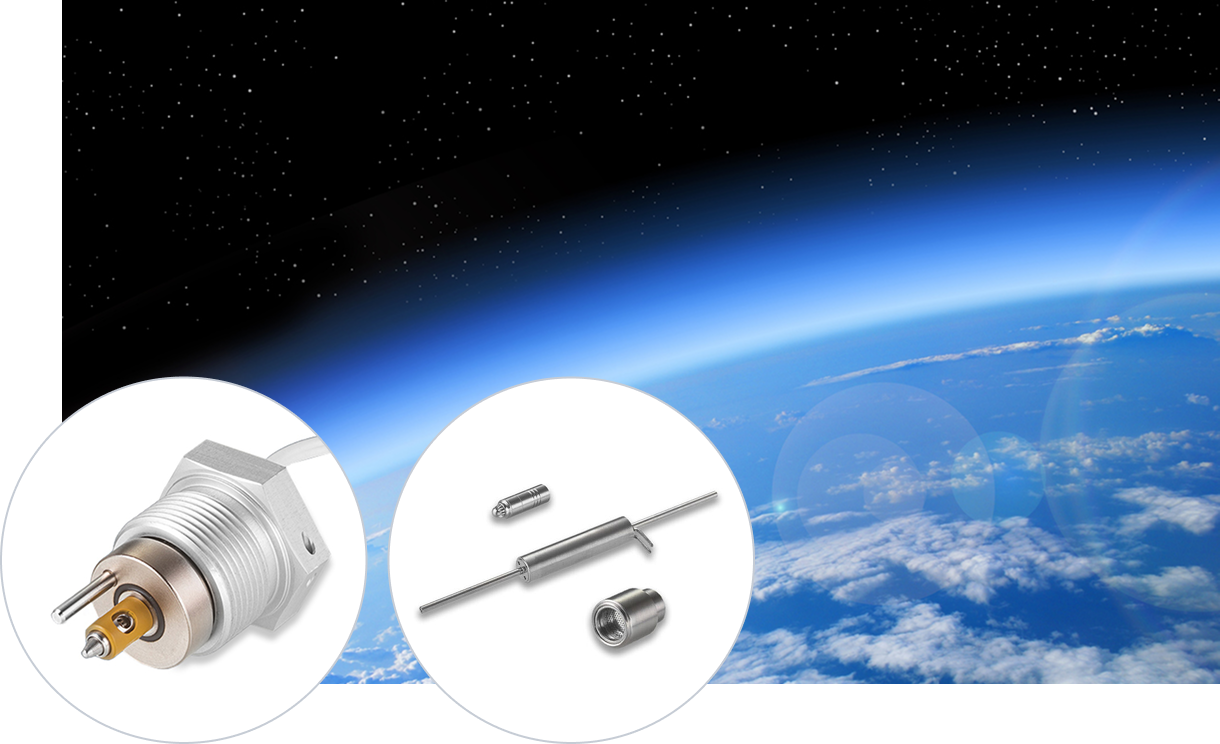

Ideal for use in propulsion, thrust vector control, stage separation, orbital maneuvering, landing, thermal management, and life support systems.

From crewed space exploration to cubesats, Lee fluid control components have been used in a wide range of systems for over 60 years.

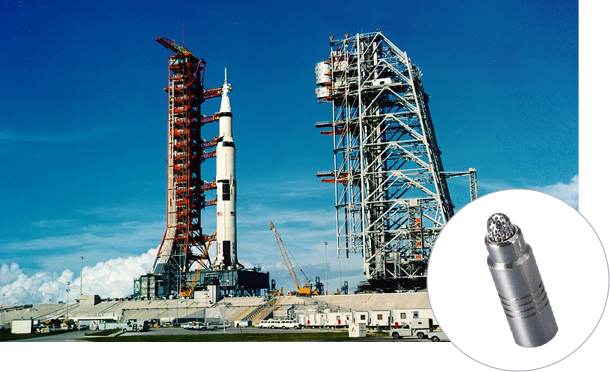

Lee components served critical roles in the historic Apollo 11 mission. They were used in the Saturn rocket propulsion system that launched the astronauts into space, as well as the orbital maneuvering system on the lunar lander which set the astronauts on the moon’s surface and controlled the flow of oxygen needed by astronauts when they walked on the moon.

Lee plugs have operated in space as early as 1961 as part of the Atlas rocket. A unique Beryllium Copper Lee Plug was specially designed to seal cross-drilled holes in copper manifolds that controlled flow from liquid oxygen tanks to the engines of launch vehicles.

Lee Jets, Lee Bender Jets, or Lee Visco Jets have been used on every U.S. and European launch vehicle since the 1960s. Ranging from commercial off-the-shelf items to custom material restrictors calibrated on nitrogen for extremely low flow with tight tolerances and cleaned in The Lee Company’s clean room.

Multiple Lee miniature fluid control components served critical functions on systems throughout the Space Shuttle. This included applications in the main engine, flight control system, and cabin accessories.

The Lee Company supplies miniature fluid control components for the International Space Station. Titanium safety screens are used in the waste system to avoid corrosion and specially calibrated Lee Visco Jets are used in the water processing and oxygen generation systems.

Lee components have traveled into deep space like the Voyager probe, and were instrumental in JAXA’s seven-year Hayabusa mission to return samples from an asteroid. We also helped equip the Cassini-Huygens space-research mission – a collaboration between NASA, the European Space Agency, and Italian Space Agency – to send a probe to study the planet Saturn and its system.

Launch vehicles require dozens of check valves throughout first and second stage propulsion systems. Lee Check Valves offer high flow in a reliable, compact package. For the space industry, The Lee Company has designed line mount configurations utilizing custom elastomeric valve seats compatible with a variety of fluids that eliminate leakage in high temperature and pressure environments.

The Lee Company’s IEP Series 2 Way Solenoid Valve, Lee JEVA, 43 Series Visco Jet® Restrictor, and Solenoid Operated Pneumatic Isolation Valve are being used by companies like EOI Space to streamline procurement, reduce design complexity, and accelerate in-house testing due to their reliable performance. Lee components are being utilized to optimize EOI Space’s Stingray commercial satellite constellation's propulsion system. The Stingray constellation will be the first U.S.-based commercial system to operate in Very Low Earth Orbit (VLEO), delivering high-resolution Earth intelligence.

Where to go from here

Looking for more information about Lee’s unique capabilities and experience in Space?

the most reliable fluid control in the galaxy

We make it our mission to solve the toughest fluid control problems in space and beyond. Whether you’re an industry mainstay or New Space start-up, we’re ready when you are.

Find the components you need with our product finder tool

Use our Product Finder tool to find the components you need for your next mission.

Contact Us

CONTACT A LEE SALES ENGINEER

Explore proven fluid control solutions designed for your needs and applications. Contact our team of Technical Sales Engineers to get started.