Precision flow restrictors built for performance

Optimize your fluid systems with flow restrictors from The Lee Company, engineered to provide consistent, reliable flow control across a range of demanding applications.

Advanced Flow Restrictor Technology for a wide range of industry applications.

Whether you need a flow restrictor orifice for fluid management or a gas flow limiter for specialized applications, our precision components deliver accurate performance, minimal maintenance, and superior durability, even in extreme conditions.

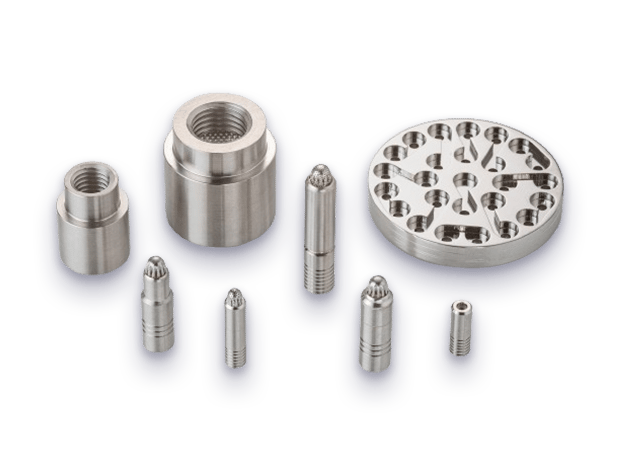

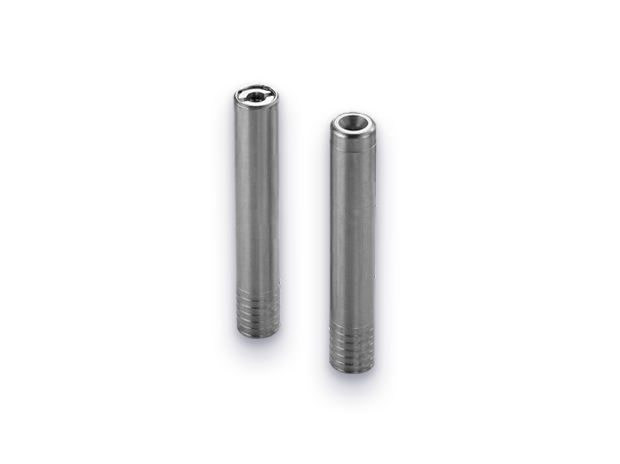

Insert Style Precision Orifices

Insert style precision orifices are economical, reliable, highly accurate miniature flow restrictors designed for metal housings. Installation is simple using our field-proven controlled expansion principle, which provides retention and a leak-tight seal without threads, O-rings, or adhesive.

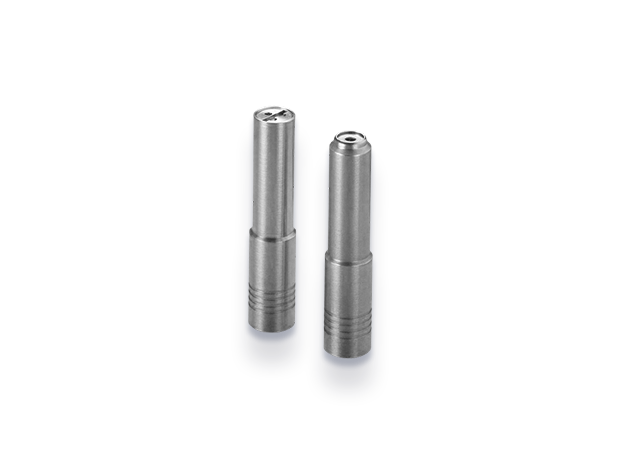

Press-In Style Precision Orifices

Designed for plastic housings, fittings, and soft-tubing. All press-in style orifices are 100% flow tested to ensure that every part is within ± 5% of its nominal flow rate and are available in both forward and reverse flow directions for both liquids and gases.

Air Bleed Orifices

These components are used to remove trapped air from hydraulic systems, increase system responsiveness, and improve reaction times. Our components utilize a small precision flow orifice that allows trapped air to escape but is small enough to restrict most hydraulic flow, minimizing system losses.

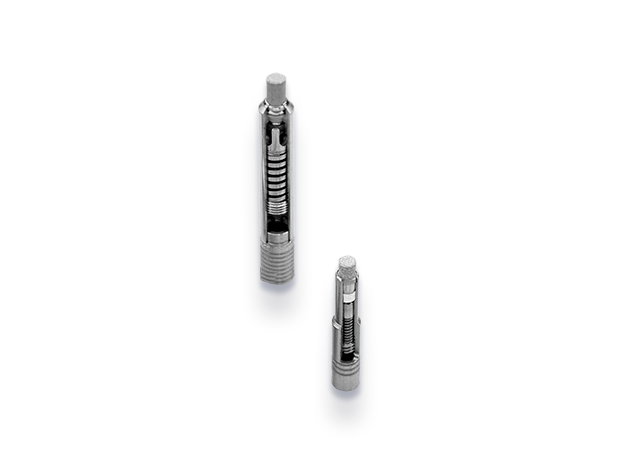

Lee Jet® Single-Orifice Restrictors

The Lee Jet is one of the most proven and reliable restrictors ever developed. These restrictors include a bi-directional precision orifice with integral safety screens on both sides. High pressure configurations are available for operating pressures up to 5000 psi.

Lee Visco Jet® Multi-Orifice Restrictors

The Lee Visco Jet is one of our most unique innovations. It creates a highly complex fluid passage with a series of individual spin chambers and orifices. There is no other product available that can provide this level of restriction with such a large minimum passage in such a tiny package.

Lee Axial Visco Jet® Multi-Orifice Restrictors

An evolution of the Bender Jet concept, Lee Axial Visco Jets don’t just bend but spin the fluid in alternating directions to create a more tortuous flow path. The result is a larger passage size than Bender Jets for a given Lohm rate, but a smaller passage size than Visco Jets.

Lee Bender Jet Multi-Orifice Restrictors

Lee Bender Jets use multiple offset orifices in series. Each additional restriction causes an increased reduction in the flow. This produces an effect that results in an increased minimum passage size for a given Lohm rate.

EXPLORE OUR FULL RANGE OF Flow Restrictors

The Lee Company offers a complete line of flow restrictors engineered for accuracy, durability, and low maintenance. From gas flow restrictors to metering orifices, our precision components support reliable fluid control across a wide range of industries and applications.

Safety Relief Valves

Designed to be fast-acting, these relief valves protect your systems from sudden pressure spikes. They come in low-leak and tight hysteresis options and undergo thorough testing for crack, flow, and reseat pressures.

Pressure Regulating Relief Valves

These valves ensure stability across the operating range and are available in various diameters and cracking pressures.

THERMAL RELIEF VALVES

Thermal relief valves protect fluidic systems from damage caused by thermal expansion by releasing small fluid volumes during rapid temperature changes.

High Pressure Safety Relief Valves

Built to handle severe operating pressures up to 5000 psi, preventing instability and damage. Available in various cracking pressures. The Hi-Q PRV is a line-removable unit designed for high-pressure, high-flow applications. It relieves up to 5400 psid and 19+ GPM, with a side inlet to minimize size and weight.

High Flow Pressure Relief Valves

The Hi-Q PRV is designed for applications that require both a high relief pressure and a high flow rate in a line removable unit (LRU). This valve can relieve pressures up to 5400 psid and flow rates over 19 GPM, and uses a side inlet flow path to minimize the installation boss size and weight.

ZERO LEAK RELIEF VALVES

Instead of relying on a metal-to-metal seal, these valves incorporate an elastomeric or polymeric seal for a zero-leak design, perfect for when eliminating leakage is a critical requirement of hydraulic or pneumatic applications.

NACE Compliant Relief Valves

The 0.281-inch NACE Compliant PRI® valve is built for harsh environments, using corrosion-resistant materials per NACE MR0175/ISO 15156. Available for pressures up to 3000 psi (screened/unscreened) and 5000 psi (screened).

Insert Style Pressure Relief Valves

Lee insert-style pressure relief valves offer secure, threadless installation with integral locking, eliminating leakage. Available in ball and poppet styles, they ensure fast response, stable flow, and high cracking pressures up to 220 bar.

Press-In Style Pressure Relief Valves

Lee press-in-style pressure relief valves feature a barbed design for secure installation in plastic housings, preventing leakage. Available in sizes from 2.5 mm to 8 mm, they ensure low leakage, repeatable cracking, and compatibility with various fluids, including medical-grade applications.

expert tips and guidance written for engineers, by engineers.

Choosing the right flow restrictor orifice is crucial to ensuring precision and efficiency in your fluid systems. Our comprehensive guide provides expert insights and practical considerations to help you make informed decisions for your specific application.

Download your free copy now to discover:

- How to select the ideal metering orifice based on flow rate, pressure, and media type.

- The key differences between gas flow limiters and liquid flow restrictors, and when to use each.

- Critical performance factors to consider, including material compatibility and clog resistance.

- Real-world applications of precision orifice technology across aerospace, medical, automotive, and industrial industries.

Download your free copy today and gain the knowledge to optimize your fluid control systems with confidence.